Driveways 101

Find Top-Rated Driveway Pros

Search NowDriveway Installation

Driveways are the paths linking the street to your home or garage, and they’re one of the first features people notice about your home. Properly installed driveways can last for at least two decades, which is why some homeowners are willing to pay extra to ensure their driveways stand out.

Gravel driveways are the most basic type, while concrete and asphalt are two of the most popular and basic driveway options. If you’re willing to spend a little more, you can have the concrete’s surface stamped to add color and texture.

Paver driveways are another option, especially if your goal is to make your home blend in with a walkway or other hardscaping feature.

Before hiring a contractor to install a driveway, you’ll need to be sure they have experience installing the specific kind of driveway you’re looking for. Each type requires specific skills and knowledge to install, and you want to be sure the contractor you hire knows how to do the job correctly the first time.

Make sure prospective contractors include base materials and plan in their written proposals. Low bids may mean they plan to skimp on the base, which will lead to a weaker driveway that will fail prematurely. Get multiple bids to compare how much base each driveway installer recommends for your project.

Concrete vs. Asphalt Driveways

Concrete and asphalt driveways are the two most popular driveway materials in the U.S. When choosing the perfect driveway surface, homeowners must consider a variety of factors, like cost, upkeep, crack repair, stain removal and regional weather.

An asphalt driveway costs less and is easier to repair, but concrete lasts longer and requires less maintenance. Angi members nationwide reported paying $7,400 on average for a poured concrete driveway, while the cost to install an asphalt driveway averaged $5,300.

While concrete and asphalt remain the top choices, there are many other alternative driveway materials on the market. Ultimately, no matter which driveway surface you pick, it's critical you hire a qualified driveway contractor who can install a drive that meets professional installation standards and plan it out properly to avert potential issues down the road, such as intrusive tree roots and poor drainage.

Stamped Concrete

Homeowners are turning to stamped concrete to give their driveways, walkways, patios and pool decks a unique look. A contractor first pours a slab with the base color mixed in. As the concrete dries, the contractor will apply highlight coloring and push down a stamp to create a pattern that can mimic brick, stone, tile or custom designs like leaves. It’s cheaper than installing brick pavers and it can last for decades if properly maintained with sealer.

Paver and Brick Driveways

Depending on the length your driveway, a paver driveway can usually be installed in about two days and is ready for use immediately upon completion.

A paver driveway will last up to 25 years and provides a unique and elegant look to your house. However, it provides a flexible surface and the bricks can shift or sink over time - resulting in an uneven driveway.

Broken bricks are relatively easy to replace. While brick driveway material costs vary greatly from region to region as well as the variances in ground conditions, brick pavers are likely to be a more expensive option.

Decorative touches or combinations of materials (brick and concrete for example) will also have an impact on the final cost.

Advantages of Pavers & Brick:

- Create stately looking properties

- Requires the least amount of maintenance of all paving options

- Last a relatively long time with desired results

- Can be created using colorful and appealing concrete pavers or bricks

Disdvantages of Pavers & Brick:

- Can be expensive to install

- Requires long installation times

- Can crack during extremely cold or freezing temperatures

- Can stain due to motor oil, antifreeze and other chemical agents

Gravel Driveways

The least expensive driveway option is gravel or crushed stone. A wide variety of crushed stone materials offer the homeowner several choices in color and overall look. Because this material is used in driveway foundations, no separate foundation is required — making this a very cost-effective option.

The gravel driveway will need to be replenished over time as the rocks settle into ruts faster than a hard surface driveway. Raking will be required on occasion to keep the rocks from getting into your grass. And while the material is not as likely to freeze, shoveling snow from a stone driveway can be difficult.

Advantages of Gravel Driveways:

- Least expensive driveway paving method

- Very little to no maintenance required

- Driveway can be used even during installation

- Can be switched to asphalt with ease

Disdvantages of Gravel Driveways:

- Has a very short life expectancy rating

- Can shift when used on a sloping property

- Does not provide the same curb appeal as other paving methods

- Does not provide a high increase to the value of the property

- Can create divots and holes from normal driving over a short duration of time

Tips for Hiring Driveway Installers

Do your homework on the various options and costs for driveway materials and decide which is best for your home and your budget.

Be extremely wary of unsolicited offers from someone who claims to to have "left over" materials from a nearby job and offers to install your driveway at a great discount. Any offer that sounds too good to be true, probably is, and puts you at risk for a driveway scam. In driveway work, even if there is asphalt or cement left over from a job, it is unlikely to be sufficient for a second job, would probably have cooled too much and therefore would not have been time to properly prepare the second driveway. The result is highly likely to be a bad driveway that will need to be repaired or replaced very quickly.

Get on-site estimates from three or more paving contractors. You may have a friend or neighbor who can recommend a high-quality local company — preferably when the job was done a few years earlier since flaws in workmanship may not present themselves for a while. If you join Angi you will be able to read reviews and ratings of specific driveway installation companies that work in your area from other Angi members in your community.

Get the job details in a written estimate. In order to obtain an accurate estimate, have a sketch of the home and the desired driveway footprint. Walk the site with the driveway paving contractor and have him/her mark where the paved driveway is to lay.

Talk to the professional driveway installer about slope and drainage. If these are not handled properly, you may end up with water pooling on the finished driveway, or draining into your garage or home.

Make sure the contractor accounts for any underground pipes so that these are not damaged in any excavation. Typically, this is not a factor when an existing driveway is being repaved, but is often a factor when a new driveway is being installed where no previous base had been established.

Compare Quotes from Driveway Pros

Search NowBefore Pouring Concrete

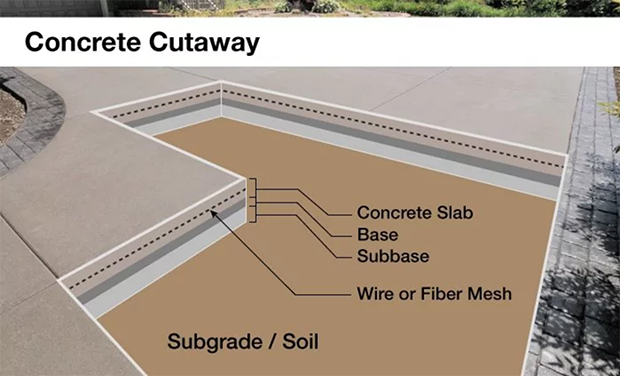

In order for a concrete driveway to last, it's imperative your contractor build a strong base before the driveway installation. A solid concrete residential driveway foundation consists of three to four layers.

Subgrade: Native or improved soil, graded and compacted. Driveway base must be graded so water sheds properly and drains away from the home or garage. Soil shouldn't be too dry or too muddy.

Subbase: Layer of gravel, typically 4-inch stone or crushed stone aggregate. Depth of base required depends on the soil in your region. You don’t need a subbase if pouring over a gravel driveway.

Base: Finer stone, such as pea gravel, may be thinly layered on top of the courser rock to help level and grade the driveway. This isn’t always necessary.

Subbase and Base layers should total 3 to 6 inches.

Concrete Slab: Minimum 4-inch thickness for residential driveways. Add wire or fiber mesh halfway through slab to add strength. For a 4-inch slab, install mesh 2 inches from top so it's not damaged when cutting control joints. Control joints should have a maximum spacing of 12 inches for 4-inch slab. Depth of joints must be 25 percent of slab thickness. Ask your driveway installer for a jointing plan as part of their written proposal, particularly for large or complicated driveways.

Total thickness: 7 to 10 inches

Asphalt: How to Build a Driveway

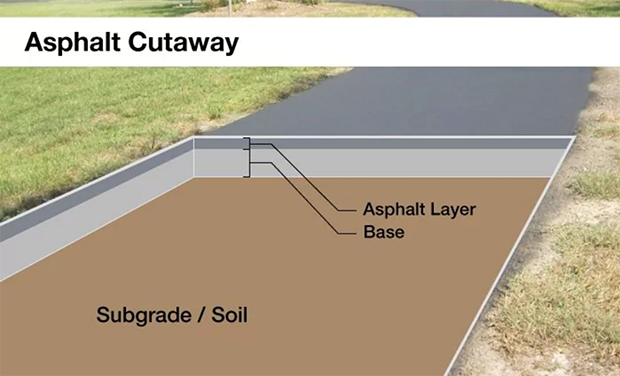

Much like concrete, an asphalt driveway requires a proper base if you want the top blacktop layer to last 20 years or more. A professional standard for asphalt driveways requires three layers of materials.

Subgrade: Native or improved soil, graded and compacted. Grade driveway so water doesn't pool in the middle and drains away from adjacent structures, such as your home. If the soil is wet or marshy, consider installing geotextile fabric before the gravel layer to keep water from seeping up and weakening the base.

Base: 3 to 6 inches of course material like concrete and asphalt aggregate or crushed gravel. This material sometimes contains a binder, such as cement dust. Make sure the gravel base is 1 foot wider than the proposed asphalt layer — 6 inches on each side. The base must be compacted well.

Base thickness is determined by soil conditions and industry standards in your region. If installing a thicker base gravel, it should be installed in two layers, compacting each you go. Let the base settle for one to two weeks before applying asphalt.

Asphalt: 2 to 3 inches of compacted hot asphalt applied with a heavy roller. For a smoother finish on residential driveways, asphalt experts recommend half-inch gravel filler aggregate asphalt. A rougher three-quarter inch aggregate can be used for the bottom layer of asphalt for increased durability. The asphalt driveway edges should be raked to form a 45-degree angle and hand tampered.

Total depth: 6 to 8 inches

Driveway Gravel: Preparing the Base

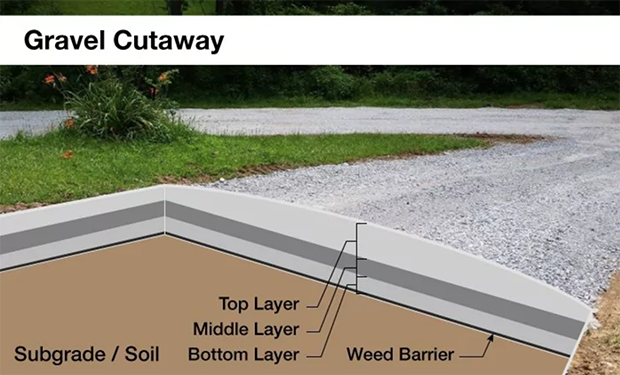

It may seem simple to install a gravel driveway, but homeowners or contractors must take the time to properly prepare the driveway base and layer the stones in a particular order. A standard residential gravel driveway consists of three layers atop the soil. Tamper down each layer with a mechanical roller or tamping machine.

Subgrade/Soil: Remove topsoil layer and any organic debris. This base must be graded and leveled.

Weed barrier: Consider installing geotextile weed barrier before any stone.

Bottom layer: Crushed rock, 6-inch diameter (#3 stone)

Middle layer: 2- to 3-inch stones (#57 stone)

Top layer: 3/4-inch rough, angular gravel that's roughly thumbnail size. It's often mixed with stone dust for better compaction, and called “traffic bound," "dense grade" or "crusher run" gravel. Do not use smooth, round rocks as they won't compact and stay in place. Crown the top layer of gravel so it peaks in the middle and gently inclines to the edges.

Each layer: 4 to 6 inches

Total depth: 12 to 14 inches

Build Your

Build Your 5 Projects to

5 Projects to Roofing

Roofing 7 Signs Your Siding

7 Signs Your Siding